CLASSIFICATION

NORTH-BENZ-BRAND

CONTACT-US

- Name: Baotou beiben Trading Co.,

- Mobile phone: 13327188003

- Mobile:13664067905

- Tel: 0472-3610990

- FAX: 0472-3610990

- Q Q:350013459

- E-mail:350013459@qq.com

Machines operating in northern China, high-altitude and cold regions should be replaced with higher grade engine oil in winter, such as 10W-30 and 5W-40 engine oil, or higher grade engine oil; For machines operating in warmer winter areas such as the south, the need for oil replacement can be considered based on the actual local temperature situation.

When selecting lubricating grease, when the temperature is high, it is recommended to choose grease with low evaporation loss and relatively thick content; In winter, when the temperature is low, it is advisable to choose oils with low viscosity and thinner viscosity.

When the excavator enters winter, it is also important to pay attention to replacing the engine cooling water of the TEREX spare parts with antifreeze with a lower freezing point to prevent damage to the cylinder liner and radiator. If the excavator equipment stops using for a period of time, it is necessary to empty the cooling water inside the engine. When draining water, attention should be paid not to discharge the cooling water too early. When the body is at a high temperature, sudden invasion by cold air can cause sudden shrinkage and easily lead to cracks.

.png)

In addition, when draining water, the remaining water in the body should be thoroughly drained to prevent freezing and expansion, as well as cracking of the body.

Winter excavators also need to do "preparation activities"

After the diesel engine starts and catches fire, do not immediately put the excavator into load operation. The excavator needs to prepare for preheating.

A diesel engine that has not been ignited for a long time, due to the low body temperature and high oil viscosity, the oil is not easy to fully lubricate the friction surface of the moving parts of the engine, which can cause serious wear and tear on the machine. After starting a diesel engine in winter and catching fire, it is recommended to idle for 3-5 minutes. Then, use the TEREX spare parts and increase the engine speed. Operate the bucket and stick to work continuously for a period of time. When the cooling water temperature reaches 60 ℃ or above, put it into load operation.

Whether it is winter construction or shutdown for winter maintenance, attention should be paid to the insulation of key components of the equipment.

After the winter construction work is completed, the engine should be covered with insulation curtains and sleeves, and if necessary, a board curtain should be used to block the wind in front of the radiator. Some engines with TEREX spare parts are equipped with oil radiators. The conversion switch should be turned to the winter low temperature gear to prevent oil from flowing through the oil radiator. If the excavator stops working, try to park it in indoor areas such as the garage.

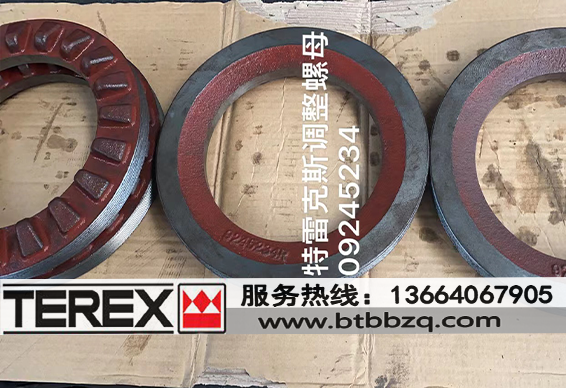

The company mainly deals in Terex spare parts for non highway rigid dump trucks TR100, TR50, TR60, TR353307/3305, and a full range of products. Terex spare parts TR100, MT3700, MT4400, MT5500, Terex spare parts, and other mining dump truck Allison transmission parts, Cummins engine parts, hydraulic seals, high and low voltage harnesses, hydraulic cylinders, machined parts, gears, chassis series parts.

*Disclaimer: The reproduced content is all from the internet. If you have any objections, please contact Terex spare parts in a timely manner. This website will delete it.